Aluminum ceiling panels are a commonly used ceiling material.

Aluminum ceiling panels are a commonly used ceiling material.

Aluminum ceiling panels are a commonly used ceiling material. They are mainly made of aluminum alloy and, after a series of production processes, boast characteristics such as light weight, corrosion resistance, fire resistance, and ease of cleaning. Now, let's follow the camera into a factory in South Korea to witness the entire production and manufacturing process.

This large roll of aluminum alloy material serves as the raw material for making aluminum ceiling panels. After passing through a leveling machine, the aluminum alloy material is immediately cut. The cutting machine slices it into the required dimensions with a clean "click," ensuring each piece is perfectly flat. The cut plates are then collected and prepared for the next step in the production line.

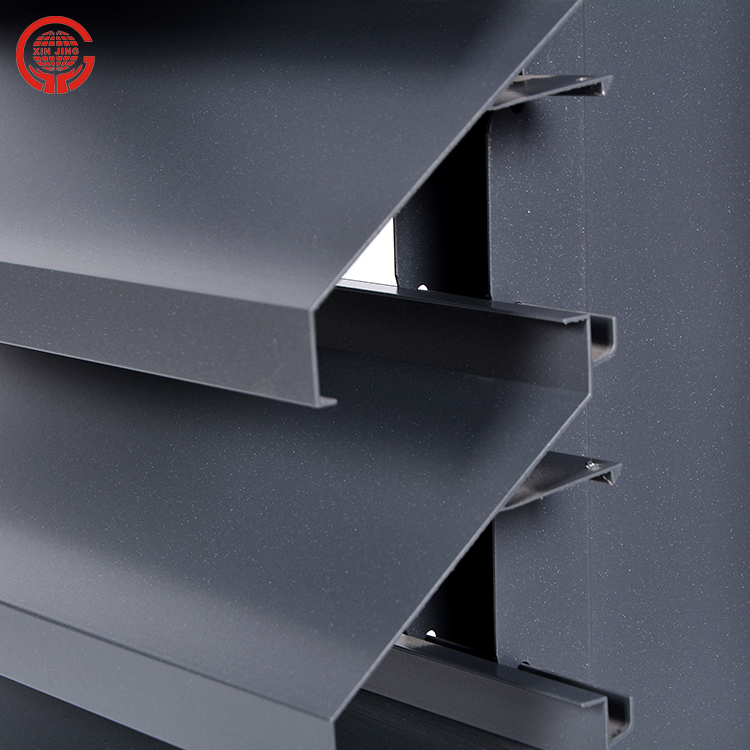

As the camera pans, we arrive at the plate - forming workshop. Here, even the material feeding is automated. We simply watch the machine operate seamlessly. Once the plate is placed in the designated position, holes are punched along its edges. It is then transferred to an adjacent stamping machine for shaping. The formed aluminum ceiling panels are placed on a conveyor belt. At this point, the production of the aluminum ceiling panels is complete, and workers can start packing and boxing them.

Of course, based on market demand, aluminum ceiling panels of different specifications and styles can be produced. The ones being produced here are perforated aluminum ceiling panels. After passing through a leveling machine, the plates first undergo hole - punching operations, followed by cutting. After cutting, they are rolled and flattened, completing the plate treatment in one go. The perforated plates need to be stamped one by one. After the edge holes are processed, they are placed in an adjacent forming machine for stamping and shaping. In this way, another style of aluminum ceiling panel is quickly formed. Machine production is truly convenient.

Perforated aluminum ceiling panels also require a layer of non - woven fabric to be attached to the back. This not only enhances their sound - absorption capability significantly but also has a heat - absorbing effect, helping to save energy. At this stage, the production of the perforated aluminum ceiling panels with non - woven fabric backing is finished. Workers roughly inspect them, stack them up, and then wipe their surfaces to ensure they are clean and free of impurities.

The clean surfaces are then ready for pattern printing. Of course, those that don't require pattern printing can be directly packed and boxed. According to customer requirements, exquisite patterns can also be printed. Aluminum ceiling panels without patterns do look rather monotonous. Look at the printing machine bustling about; patterns soon appear on the aluminum ceiling panels. Although the printing machine works efficiently, it does add an extra step to the production process. It's no doubt that aluminum ceiling panels with a coating are more expensive.

Just like the flat - panel type, perforated aluminum ceiling panels can also have patterns printed on them. Simply leave it to the printing machine. Soon, images of blue skies and white clouds appear on the aluminum ceiling panels. After printing, they are placed on special shelves for a period before being packed.